For many years, material scientists have long thought that some empty areas on the compressive strength-density chart should be filled by materials that theory predicts. Computer simulations could be used to indicate an optimum microstructure that would give a material the right properties. However, nobody had tools to build materials with defined patterns at the scale of a human hair.

With recent developments in lasers and 3D printing, however, a German company called Nanoscribe started offering lasers that could do just what Bauer wanted. Nanoscribe's system involves the use of a polymer that reacts when exposed to light and a laser that can be neatly focused on a tiny spot with the help of lenses.

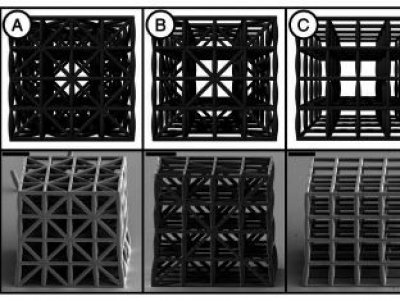

A drop of a honey-like polymer is placed on a glass slide and the laser is turned on. A computer-aided design is fed into the system, and the slide carefully moves such that the laser’s stationary focus touches only those points where the material is to be made solid. Once complete, the extra liquid is washed away, leaving behind materials with intricate internal structures.

However, these materials on their own are not as strong as Bauer wanted. So he coats them with a thin layer of alumina (aluminium oxide) before subjecting them to stress tests. Based on the tests, he was able to improve the theoretical models he used to design the internal structure of the materials.

Even though alumina layers increase the density of these materials, all of them remain lighter than water. Bauer's strongest material has a specific honeycomb internal structure and is coated with a 50 nanometer-thick (billionth of a meter) layer of alumina. It beats all natural and man-made materials that are lighter than 1000kg/m3, being able to withstand a load of 280MPa (mega pascals is a unit of measuring pressure), which makes it as strong as some forms of steel.

However, there have been rapid improvements in all the areas this work relies on: 3D printing, new polymers, and laser technology. That means we may soon have a suite of new, super lightweight materials for everything from skis to aircraft parts. If nothing else, Bauer’s work shows that we are definitely in the molecular age.